Duoline 20 Composite-Lined Tubulars. Delivering superior Corrosion Protection in extreme downhole environments.

The workhorse of our DUOLINE® lining systems. DUOLINE® 20, developed in 1971, is targeted at demanding corrosive downhole environments. With a proven track record in a great number of demanding environments including water injection, CO2 injection, gas production, gas-lifted oil production and chemical disposal wells, Duoline 20 Composite-Lined Tubulars are the only choice to be made when you have corrosion issues.

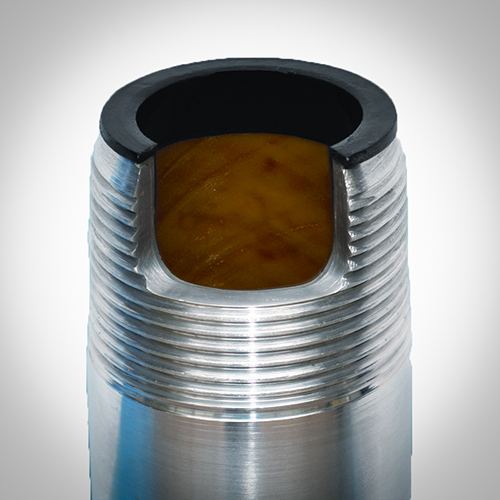

What is Duoline 20? An engineered system consisting of a Glass Reinforced Epoxy (GRE) lining and an elastomeric Corrosion Barrier Ring (CBR) lining, the Duoline 20 process eliminates the “holiday” potential created by IPC coatings. Installed in both new and used tubulars, Duoline 20 is manufactured by inserting a rigid Glass Reinforced Epoxy (GRE) tube into steel pipe and filling the annular space with a special mortar applied with pressure. The liner is continued around the end of the pipe with a molded flange, known as the “flare”. A specially designed reinforced elastomer corrosion barrier ring (CBR) is compressed in the coupling by the opposing flares.

GRE or “fiberglass” pipe is used very extensively in the oil, gas and chemical industry for low pressure oil and gas transmission, salt water disposal, chemical piping system, etc. GRE is a composite material formed from thermosetting epoxy resins with continuous fiberglass filament reinforcements which gives a superior hoop strength and is resistant to chemical attack from many common oilfield chemicals

The Corrosion Barrier Ring (CBR) protection of the connection area is the strength of the DUOLINE ® process. After all, what benefit is realized from a premium pipe coating or lining that permits connection corrosion? Most coated tubing corrosion failures originate in the connection area. Duoline employs a reinforced elastomeric CBR compressed between the liners in the connection make-up process. For API connections, Rice provides a propietary ring with spring steel wire reinforcements, which hold the ring in place during pressure cycles. And for premium connections, a glass-reinforced PTFE (Teflon) CBR that is exclusively designed for the Duoline system for proprietary connections.

Liners have been criticized for reducing the internal annulus of production tubing, potentially reducing flow. However, Duoline 20 can handle more fluid over the life on an installation, due to the deterioration of bare pipe with age and subsequent reduction of the Hazen William’s “C” factor. And, with installations up to 144°C in highly-concentrated H2S or CO2 environments, we are proud to carry an excellent track record in sour gas production, acid gas disposal, sour water reinjection, CO2 injection and Water-Alternate-Gas (WAG) CO2 injection.

We would be happy to share our experiences with you – please chat with us online, contact us or call us today for a recommendation based upon your application parameters.

| Sign up for a MY RICE Account | Sign up for the RICE Newsletter | Sign up for a MY RICE Account | Sign up for the RICE Newsletter